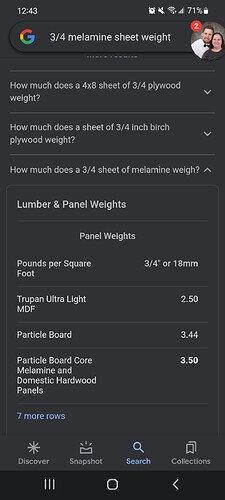

I’m looking to build a melamine rack for my leopard geckos. The only problem I’ve found is that it is very heavy. Does anyone have an estimate of exactly how heavy it is? My rack needs 4 sheets of 3/4" 4’x8’ melamine. I’m not sure if I can make it as one piece or if I need to make it in multiple sections that stack.

Each sheet weighs 95lbs, so you’ll be looking at a total of 380lbs plus tubs, tape, screws, casters, etc

@jverz @chesterhf Thank you both! I think I’m going to make it in sections with a few shelves for each section.

Weve built 4x2x2 enclosures oht of melamine and theyre heavy af. But also super awkward. I definitelythink sections is a better option. Especially if you dont have somebody handy to help you move them when ya need to.

As an update I’m going to make it in 4 sections of two shelves with an extra shelf instead of 9 shelves. I’m also going to use foam board for the back. I figured the 2 benefits of a back were support and insulation. I’ll use one or two threaded axles to hold the shelves up in the middle and I’ll use foam board on the back for insulation. It’s still heavy but lighter and easier to use than melamine.

Maybe try the insulation panels that are like foil lined styrofoam? They’re pretty light, easy to cut to size, not too expensive.

Like the idea of the threaded supports for the shelves, lighter weight and you could design it so they’re adjustable for height so different tubs could be used. Makes the setup more adaptable, you could change tubs for the animals as they grew over time wuthout having to build a whole new setup.

Dang it, now I have to go do a redesign…

With this design I can fit nearly 50 6 qt tubs. So that’s another benefit I had for the axles. I would have to move the screws on the side but it’s still possible to use it for 6 qt tubs.

See, I’m thinking if you made the shelf height adjustable, the depth doesn’t matter, you’ll just push the tub, no matter what size, all the way to the back on the heat tape. But being able to raise the height of the shelves means you could go from say 4 across 6qt tubs to 2 across 23qt tubs so you could change it to a grow out rack, then later to 1 70qt.

True, fewer tubs, but as you sell hatchlings, or need to convert to a growout rack?

Also, adjustable height means you could use any tub made by anyone as long as all the tubs on the shelf were the same height. No more being stuck waiting for a particular manufacturer of tubs to be in stock, or having to make perfect measurements when building. You would just move the stops to the appropriate height.

Might even be able to get rid of the melamine altogether and really save weight. Dang it, now I really have to go do a redesign. If I can get rid of the melamine, I don’t have to worry as much about humidity, weight, paint, steel might be cheaper?..

Let me get back to you on this…

If you decide to do something with this let us know. This is super interesting. If I had more money and space I would experiment with PVC and/or metal.

I’m thinking a really simple skeleton of metal with threaded rods and jam nuts for the uprights. Need to figure out the weight bearing and stability. The sides can be enclosed to a greater or lesser degree by the insulation panels if they aren’t weight bearing. Maybe thin sealed sheets of plywood for the shelves themselves?

Ehh, I’ll work on it, my goal is something simple any reasonably handy person can build with almost no tools and with a single, relatively, cheap trip to a decent hardware store. I’m trying to get away from weight, high cost materials, hard to source materials, proprietary tub sizes, etc. You get the picture. But it might just be cheaper to buy a premade wire pantry rack and modify it…

If I get a good working model, I’ll post it.

So mine isn’t adjustable to different tub sizes (which would be super cool/convenient), but it is modular like IKEA furniture. The shelves slide out, and the sides/back are held toether with a few nuts/bolts ,and when taken apart the whole thing lays flat. We built it this way because I’ve already transported it from Pennsylvania back to Texas, and now will likely have to move again with it. As a smallish person, I can’t move or lift this rack, but the pieces are easy to handle

Definitely, modular is the way to go if you aren’t just dropping it onto a dolly from the back of the truck and then wheeling it across a flat concrete floor like a warehouse or garage. Gotta go through a door or over a lip or up almost any stairs? You don’t want to do that with full sheets of melamine or a solid 6 foot tall, 5 wide steel rack. And if you don’t have a big truck and helpers? Yeah, I’ll make extra trips with parts, thank you muchly.

My 4x2x2 built out of 1 sheet of 4x8x3/4 weighs about 150lbs with glass and bedding if i had to guess if that helps lol